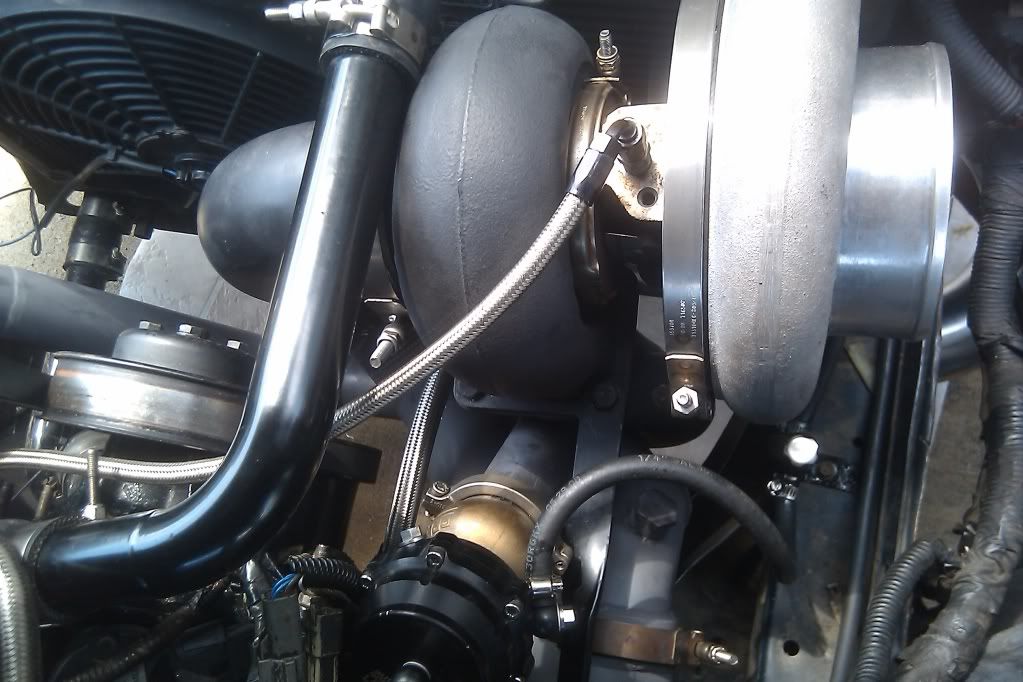

How do you have your turbo supported? After nearly every drive I am getting cracks on the hot side piping and I believe it to be because the turbo is not supported by anything other than the piping itself. There is no flex coupler on the hotside either. At this point I have a crack on the drivers side header and at the wastegate. The cracks form just above/below the weld.

I am not home very often and would like to drive it instead of work on it when I do get time at home.

Also the rear differential mount keeps cracking. Has anyone used the mount that Bill at SCP is selling with success?

Any tips, advice, and pictures of how yours are supported is appreciated.

Thanks,

Chris

I am not home very often and would like to drive it instead of work on it when I do get time at home.

Also the rear differential mount keeps cracking. Has anyone used the mount that Bill at SCP is selling with success?

Any tips, advice, and pictures of how yours are supported is appreciated.

Thanks,

Chris